The demand for high-quality electrical panels is growing rapidly across industrial, commercial, and residential sectors. A well-manufactured panel ensures safety, reliability, and efficient power distribution.

In this complete guide, we break down the entire electrical panel manufacturing process, covering panel types, components, international standards, and quality testing.

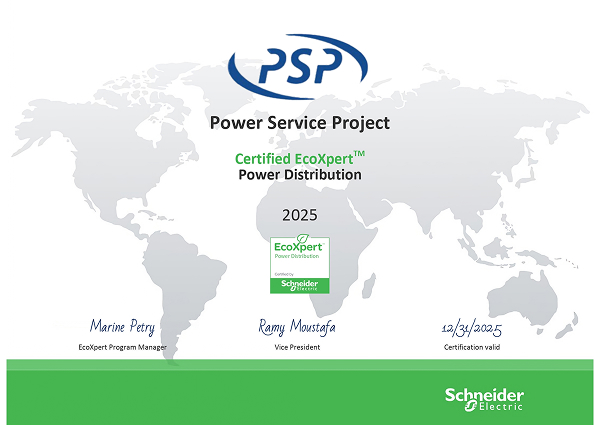

We also explain why choosing a Prisma Certified EcoXpert partner gives you superior performance and guaranteed compliance.

Table of Contents

1. What Are Electrical Panel Manufacturing?

Electrical panels (distribution boards, control panels, or switchboards) are metal enclosures containing the components used to safely distribute and control electrical power. They are essential for protecting circuits, preventing overloads, and ensuring stable power for all systems.

2. Types of Electrical Panels

2.1 Main Distribution Board (MDB)

Receives power directly from the utility and distributes it to SMDBs.

2.2 Sub-Main Distribution Boards (SMDB)

Power supply for specific floors, zones, or large equipment groups.

2.3 Final Distribution Boards (FDB)

Provide final distribution to lighting, sockets, and small circuits.

2.4 Motor Control Centers (MCC)

Used in factories for motors, pumps, conveyors, and industrial automation.

2.5 PLC Control Panels

For automated systems using programmable logic controllers.

2.6 Synchronization Panels

Sync and control multiple generators.

2.7 ATS (Automatic Transfer Switch) Panels

Automatically switch between the main power and the backup generator.

3. Components Used in Electrical Panel Manufacturing

Key components include:

- Circuit breakers

- MCCB / MCB

- Busbars (copper/aluminum)

- Contactors & relays

- Surge protection devices

- Terminal blocks

- Wiring & cables

- PLC modules

- Control switches

- Digital meters

- Enclosures

4. Step-by-Step Process of Manufacturing Electrical Panels

4.1 Load Study & Requirements Analysis

Understanding load capacity, safety needs, voltage, and control requirements.

4.2 Electrical Design (SLD)

Creating a detailed Single Line Diagram showing all circuits and protections.

4.3 Mechanical Design

Choosing enclosure dimensions, thickness, layout, and thermal management.

4.4 Component Selection

Selecting reliable components based on ratings, brand, and standard compliance.

4.5 Enclosure Fabrication

Cutting, bending, welding, and powder coating the metal enclosure.

4.6 Busbar Manufacturing

Cutting, bending, drilling, and insulating copper or aluminum busbars.

4.7 Component Mounting

Mounting breakers, contactors, PLCs, relays, and meters according to layout.

4.8 Wiring & Labeling

Power and control wiring, labeling every wire and component for safety.

4.9 Panel Testing

Complete functional testing before delivery.

5. International Standards & Certifications

Manufacturing should comply with global standards such as:

- IEC 61439 – For LV switchgear

- IEC 60204-1 – Machine safety

- ISO 9001 – Quality management

- IEEE standards

- UL Listings (for certain markets)

6. Quality Control & Testing

Standard panel testing includes:

- Visual inspection

- Wiring continuity test

- Insulation resistance test

- High-voltage withstand test

- Function and simulation test

- Thermal test (if required)

7. Common Challenges in Panel Manufacturing

- Incorrect busbar sizing

- Poor wiring organization

- Insufficient ventilation

- Low-quality components

- Wrong short-circuit ratings

- Lack of documentation

8. Applications of Electrical Panels

Electrical panels are used in:

- Industrial factories

- Commercial buildings

- Hospitals & healthcare facilities

- Data centers

- Oil & gas projects

- Water treatment plants

- Residential buildings

- HVAC and automation systems

9. Prisma Certified EcoXpert – Schneider Electric

Being a Prisma Certified EcoXpert partner by Schneider Electric is one of the highest achievements in the electrical industry.

This certification guarantees:

9.1Compliance with Schneider’s PrismaSet Architecture

Using PrismaSet systems approved for IEC 61439 ensures maximum safety.

9.2 High-Quality Components

All components (breakers, MCCBs, busbars, digital systems) are Schneider-branded and globally trusted.

9.3 Advanced Energy & Digital Monitoring

Integration with Schneider’s EcoStruxure platform for digital monitoring, protection, and energy management.

9.4 Certified Assembly Process

Panels are assembled following Schneider Electric’s strict global standards.

9.5 Global Recognition

EcoXpert partners are recognized worldwide for delivering premium, safe, and future-ready electrical panels.

10. Best Practices for High-Quality Panel Manufacturing

- Follow IEC 61439 and other standards

- Maintain proper air circulation

- Use high-quality certified components

- Separate control & power wiring

- Use clear labeling

- Test each panel fully before delivery

- Document everything (SLD, manuals, test reports)

11. Why Choose Us — About Our Company

We are a specialized electrical engineering company with extensive experience in manufacturing high-performance electrical panels for industrial, commercial, and infrastructure projects.

Why Clients Trust Us?

Prisma Certified EcoXpert (Schneider Electric)

We are officially certified to design and assemble Schneider Electric PrismaSet panels following the highest global standards.

Guaranteed Compliance

Our panels comply with IEC 61439, IEC 60204-1, and other major international standards.

Premium Components Only

We use Schneider Electric components to ensure long life, high efficiency, and maximum safety.

Expert Engineering Team

Our engineers are trained and certified to deliver reliable, high-quality electrical solutions.

Full Testing & Documentation

Each panel is delivered with:

- Test reports

- SLD drawings

- Component datasheets

- Operation & maintenance manuals

Custom Designs for Any Project

We build panels for factories, buildings, hospitals, automation systems, water plants, and generator systems.

Long-Term Support

We offer maintenance, upgrades, and on-site troubleshooting.

If you want, I can rewrite this section using your company name, mission, services, and tone — just tell me the name and details.

12. Conclusion

Manufacturing electrical panels requires engineering expertise, strict safety standards, and high-quality materials. Working with a Prisma Certified EcoXpert ensures maximum reliability, safety, and long-term performance.

Whether it’s MDB, SMDB, MCC, PLC panels, or synchronization systems, choosing the right manufacturer can significantly impact your project’s efficiency and safety.

13. FAQ

What is the benefit of working with a Prisma Certified EcoXpert?

It ensures your panels are manufactured with Schneider Electric standards, using certified components and architecture.

What standards do electrical panels follow?

The primary standard is IEC 61439, along with IEC 60204-1 for machine safety.

How long does panel manufacturing take?

Small panels: 3–7 days

Industrial MCC/PLC systems: 1–4 weeks

Do you provide testing and certification?

Yes, all panels undergo full testing and are delivered with comprehensive documentation.

Can the panels be customized?

Yes, all panels are fully customized based on project requirements.